Spacious quarters improve lives of temporary foreign workers

KAREN DAVIDSONHeated floors. Airy living room with big-screen TV. Stainless steel kitchen. These are a few of the favourite things that Victor Lugo and Eduardo Bautista are enjoying in new living quarters.

They are temporary foreign workers (TFWs), part of the two-year AgStream program, who took up residence the first week of January 2023 at Meyers Fruit Farms, Niagara-on-the-Lake, Ontario.

“I feel like a master chef in this kitchen,” says a grinning Victor Lugo whose favourite dish is chilaquiles –a Mexican tortilla stuffed with green or red salsa, pulled chicken, cheese, refried beans and scrambled eggs. “I love all the tools here and the stainless steel kitchen is easy to clean.”

For Eduardo Bautista, he enjoys the big windows that

look out onto peach groves. The two Mexicans are part of a vanguard of workers who are tending the 25 acres of floral greenhouses or pruning 350 acres of peach trees and vineyards of Meyers Fruits Farms.

So far, 2023 has been a go-ahead year after the pandemic revealed that housing needed to properly space a peak number of 80 workers.

“We had to cut back our number of workers by about 15 per cent in 2022 to accommodate spacing needs,” says Aron Hoff, vice-president of production, Meyers. Fruit Farms. We house workers at a number of different facilities on different farms. But the challenge for us has been the expense of rental space while our needs for labour are growing.”

To meet these needs, Meyers Fruit Farms contracted a local building company, Smart Homes Niagara, to construct five 1,904-square-foot houses a year ago. The ambitious goal was to finish by August 2022, but delays in

material arrivals pushed the schedule to early 2023.

The results are worth the wait. Steel structural insulated panels provide affordable, comfortable, and energyefficient housing units for year-round living. They include a combined mudroom/laundry room upon entry at the back of the unit. A long hall, with bedrooms and bathrooms to left and right, leads to the brightly lit kitchen and living area. Stainless steel cupboards and countertops sparkle alongside two of all the major appliances: stoves, microwaves, refrigerators and sinks. These doubles accommodate cooking by eight people.

“The main challenge in building these houses was to limit the number of people per house so that the 10,000litre limit was not exceeded in the septic system,” says Hoff. “This was valued advice from other farmers in the area.” Continued on page 3

Lakeside Produce Inc.

files for bankruptcy

KAREN DAVIDSONGreenhouse vegetable grower Lakeside Produce Inc., headquartered in Leamington, Ontario, filed for bankruptcy on January 17, 2023, owing $188 million to a broad swath of suppliers ranging from freight logistics, packaging and brokerage firms in Canada to greenhouse companies in the United States, Mexico and the Netherlands.

With $166 million in secured debt to the Bank of Montreal and Farm Credit Canada, the trade creditors will be hardest hit with $22 million in arrears. Several Ontario greenhouse growers are owed considerable sums, totalling more than $2 million. In Canada, the ripple effects will also be felt by greenhouse growers as far afield as Alberta and British Columbia. The degree of hurt for logistics, packaging and transport companies will depend on their size. Again, the pain will be felt mostly in southern Ontario.

The reverberation will

continue to American companies in California, Arizona, Texas, Florida and elsewhere.

Particularly hard hit are a number of greenhouse-growing companies in Mexico.

The family-owned company under the leadership of president Chris Cervini produced greenhouse cucumbers, peppers and specialty tomatoes. The team has focussed on delivering fresh, flavourful produce to families for 75 years. Anthony Cervini led the company for many years before handing over day-to-day operations to his son, Chris. The bankruptcy filings list $3.5 million in assets.

According to LinkedIn, Lakeside has conventional and organic greenhouses, warehouses, pack houses, and distribution centers spanning across North America including Leamington, Ontario, Taylor, Michigan, and McAllen, Texas. As of the bankruptcy announcement, the company’s website is no longer being maintained.

Industry perspective

Richard Lee, executive director, Ontario Greenhouse Vegetable Growers cannot comment on any individual member, but predicts that the sector is facing some challenging times specifically due to inflationary pressures felt globally.

“We are not exempt from the increases in input costs, labour challenges and supply chain disruptions,” says Lee. “The only unique thing about this financial

climate is that all prices have increased across the board at the same time. Our members are facing historically low returns for their produce, rising input costs that include labour, heat, water, packaging, transportation and taxes while trying to manage our day-to-day activities to support food security in North America. As we focus on post-pandemic activities, Ontario farmers will be engaged in a fight for survival and the ability to remain sustainable.”

With these combined pressures, consolidation is the buzz word in every sector. “From what I’ve experienced, nothing is impossible and the cards are stacked against the supply service companies that we all heavily rely on,” Lee says.

As the Lakeside Produce bankruptcy shows, the interconnectedness of the greenhouse business is global. No one is exempt from these increased costs or changes in borrowing terms at higher rates of interest.

“I think bankruptcies and consolidation will occur globally and we will learn from these economic highs and lows for years to come,” Lee concludes.

Ernst & Young Inc, the insolvency trustee, has announced that a meeting of creditors will be held February 2, 2023 at 1 pm.

NEWSMAKERS

Dr. Sikkika Mithani, president of the Canadian Food Inspection Agency that oversees plant and animal health, and food safety has resigned effective January 20, 2023. She had been in the role for almost four years.

Algoma Orchards, the largest independent apple grower and packer in Canada, has announced that Eric Biddiscombe has joined the executive team as director of sales and business development.

Kirk Kemp, president, said, “Eric is very well respected on both the vendor and retail sides of the business with a very diverse leadership background in supply chain, process improvement, merchandising, procurement, QA, packaging and produce sales.”

The Potato Growers of Alberta have announced the 2023 board of directors. James Bareman, chair is joined by Tony Kirkland, vice-chair and the following directors: Alison Davies, JP Claassen, Lloyd Ypma, Matthew Visser and Delbert Vossebelt.

Peak of the Market welcomes Taylor Fenn as director of marketing and communications. Her professional career began with an internship at Sobeys Inc before moving into positions in the private and public sector in the last eight years. “I’m proud to be joining a made-in-Manitoba organization alongside a team that’s committed to excellence and giving back to the community,” said Fenn.

Dr. Peter VanderZaag, a potato grower and international researcher, has been named the new president and CEO of the World Potato Congress. He farms near Alliston, Ontario with his daughter Ruth and son-in-law Nick at Sunrise Potato. He has served in numerous roles in international potato research and development with the International Potato Center and as a visiting professor at Yunnan Normal University in Kunming, China.

He is joined by Dr. Nora Olsen as vice-president. She is a professor and potato specialist with the Department of Plant Sciences at the University of Idaho. New board director is Brian Douglas, who brings experience as a former general manager of the organization. The 12th World Potato Congress will be held from June 23-26, 2024 in Adelaide, Australia.

Jennifer Wright has been appointed to the role of executive director of the Canadian Agricultural Human Resource Council (CAHRC). She has worked with the Canadian Agricultural Human Resource Council as a consultant for more than 19 years, and joined the organization as a staff member in 2019. In April 2021, she was appointed to the role of acting executive director. She grew up working in her family’s farm equipment dealership and helping on the farm in southwestern Ontario. She has worked in the field of human resource research and development for more than 29 years.

Condolences to the family and industry friends of Bart Huisman, 80, former Grape King and director of the Grape Growers of Ontario. He passed on January 13, 2023, just months short of his 60th wedding anniversary.

Fresh Vegetable Growers of Ontario have elected its 2023 board with Norm Charbonneau as chair and Mark Srokosz as vice-chair. They are joined by the following

Congrats to Dr. Wendy McFadden-Smith, OMAFRA tender fruit and grape IPM specialist. She’s the 2022 Award of Merit recipient from the Niagara Peninsula Fruit and Vegetable Growers’ Association. An event to celebrate her career is planned for April 2023.

Spacious quarters improve lives of temporary foreign workers

from page 1

Municipal permits for this type of housing was easy to get in the Niagara region, taking about four to six weeks. But to move ahead with any more construction on this specific property would take up to two years of planning, due to provincial requirements and engineering reports.

“If we decide to build on a separate property, then there will be no problem,” Hoff adds.

Both Meyers and Hoff repeatedly mentioned the ease of cleaning these new properties. There is no housekeeping

personnel – as in a hotel – so it’s incumbent for the residents to keep themselves organized.

“We’ve had to rely on temporary relief agencies in the past, and that means training an average of 13 workers per eason,” says Hoff. “If we can hire more long-term TFWs, then we don’t have to hire temps. New housing is a way to attract TFWs.”

Elly Hoff, vice-president, human resources and administration, Meyers Fruit Farms, agrees. She’s the go-to person for any concerns that workers have.

Interestingly, when plans were being plotted, it was decided to orient the front

porches towards the peach groves a few metres away. Little did she know how much she would like the orchard perspective. After all, she is living in one of the units while her fire-ravaged house is being restored.

The Grower is “Digging Deeper” with Aron Hoff, vice-president, production, Meyers Fruit Farms, Niagara-on-theLake, Ontario. He’s been project manager for new housing units that will accommodate up to 40 temporary foreign workers this season. This podcast is sponsored by Cohort Wholesale.

The Ontario Fruit & Vegetable Convention is hosting a labour session on opening day, February 22. It will be chaired by Stefan Larrass, a senior policy advisor for the Ontario Fruit and Vegetable Growers’ Association. One of those panels will discuss growers’ experiences with building new TFW worker housing in recent years, featuring Hayden Dooney, Suncrest Orchards and Fred Meyers, Meyers Fruit Farms.

As Larrass explains, the COVID years have been a blur when it comes to worker housing rules, but employers don’t always have the luxury of waiting for more predictable rules before investing in new housing for their workers.

“Growers have had to make decisions in somewhat of

an information vacuum, while trying to do their best to give workers a nice living space and also keeping costs reasonable,” he says. “This is why we thought it would be helpful for growers to hear from a panel of fellow growers who have gone ahead with these significant investments during the pandemic era.”

When it comes to housing inspections, the federal and provincial frameworks are actually back to being pretty reasonable now that the pandemic has tapered off, says Larrass. If a grower has issues with inspections, it’s usually because of challenges with local municipal officials who have a say over the approval of the housing (e.g. fire department, building department, local public health unit). Because of this, the housing inspection experience can vary

greatly from municipality to municipality.

The timelines for consultations on federal housing standards are in flux. This file has moved in fits and starts since the launch in 2020.

“We do expect more consultations this year since the feds have promised that the draft of the first instalment of housing standards/regulations would be coming out by early 2023, and that this first instalment would be implemented -- i.e. enacted into law -- by 2024,” says Larrass. “They’ve also signalled they want a second and third instalment of housing regulations in the coming years, so we expect more consultations on that as well.”

Okanagan Crush Pad marks changes to its business model

After 11 years running Canada’s first purpose-built custom crush winemaking business, the team at Summerland Winery is renaming to Haywire.

Winemaker Matt Dumayne, Haywire Winery says the business is committed to organic farming and sustainable winery practices, with an added passion for creating wines in concrete vessels.

When Okanagan Crush Pad opened its doors, the winery was constructed with a capacity much

larger than what was needed for Haywire, with the intention of sharing the space until its own production grew. The available space was used to incubate other B.C. winery startups.

The custom crush service offering has run its course for the team as sales of their own wines have grown and now house brands have taken over the production space that was previously used for clients. Over the past five years the team has

been actively reducing custom crush as they move towards capacity.

Along its 14-year-history of vintages, Haywire has grown from a tiny virtual wine to become the anchor brand in the Okanagan Crush Pad portfolio of wines, with recognition across Canada and in Europe.

The winery closed in 2022 for renovations. The winery is set to re-open this coming spring, with a new 1,500-square-foot modern

Growers can rest acres with blueberry scorch and plant cover crops

The B.C. government is partnering with the Delta Farmland and Wildlife Trust on a new project that will support local food producers to improve soil health and mitigate the effects of climate change in the Fraser River estuary.

“Healthy soils are vital for growing food on B.C. farmland, and our government is committed to supporting producers move toward regenerative agriculture practices that will improve soil health,” said Lana Popham, former minister of Agriculture and Food. “Regenerative

agriculture is a strong defence against the effects of climate change and implementing these practices will help ensure we have a resilient ecosystem, while strengthening local food security.”

The $150,000 project will provide educational support and offer funding for specific programs that promote the sustainable use of agricultural land in Metro Vancouver, including: • grassland set-aside program promoting the incorporation of perennials in annual crop rotations to improve soil health;

• winter cover crop program in which participants plant cover crops after the summer harvest to improve soil fertility and protect soils from erosion over the wet, winter months;

• blueberry rest program, which will offer financial assistance to blueberry growers who remove blueberry fields that have become unproductive due to scorch virus and plant soil-regenerating cover crops; and

• climate-focused soil health educational materials featuring annual field tours, printed resources and online content.

Michele Rogalsky recognized for contributions to Farm Management

Lauded

Agricultural Excellence Conference hosted by Farm Management Canada.

Now in its twentieth year, the award honours individuals or

groups who have made an extraordinary contribution to advancing farm business management in Canada.

Michele Rogalsky has dedicated her career to the advancement of agricultural education and training, retiring in 2022 from the University of Manitoba, School of Agriculture after 33 years of service. She spearheaded a critical revitalization of the two-year Diploma in Agriculture program, transforming the curriculum into one of the top applied farm management and production agriculture training programs in Canada

As part of the renewed curriculum, she engaged with industry technology partners to integrate digital agriculture which resulted in a new course titled “Agricultural Technologies for Farm Management Decision Making” which has brought together agricultural tech firms with students to explore and evaluate instrumentation and digital analysis platforms at the

The project will contribute to healthier soils, increased food production and stronger local food security over the long term.

University of Manitoba’s Carman research station and on their own farms.

Under her guidance, the School of Agriculture has established itself as a farm safety education and training leader, and she has facilitated a collaboration with Brodenhead Ojibway Nation to incorporate growing Indigenous foods and medicines, exploring sustainable food systems, nutrition, land stewardship and business practices.

Throughout her career, Rogalsky served on a number of industry boards including the Canadian Agricultural Safety Association, the Canadian Agricultural Human Resources Council, and as chair of the Canadian Association of Diplomas in Agriculture Program.

Source: Farm Management Canada December 19, 2022 news release

PEI potato industry calls on Ottawa to listen to international experts

The Prince Edward Island (PEI) potato industry welcomed the final report of International Advisory Panel (IAP) on Potato Wart that was presented to industry and government on January 16, 2023. The panel was convened by the Canadian Food Inspection Agency in 2022, as follow-up to potato wart detections in PEI in October 2021.

The panel was comprised of world-renowned experts in potato wart from Germany, the Netherlands, Northern Ireland and New Zealand. The Panel’s main purpose was to obtain the advice of leading experts on testing diagnostics, surveillance and management of potato wart. The experts also examined whether existing wart management activities meet International Standards to certify potatoes for international export.

The PEI potato industry is pleased with the thoroughness of the panel report and the Panel’s key findings that “Given the limited presence of the pathogen, the IAP considers most parts of PEI outside the Regulated Fields as a PFA (pest free area) for S. Endobioticum.”

This conclusion is important because the Ministerial Order established by the federal government in November 2021 said that the entire province of PEI was “infested” with potato wart, which this report now demonstrates was an over-reaching, misleading label that offended PEI farmers and was accompanied by severe restrictions.

The IAP report also confirmed that the general and specific surveillance activities on PEI since 2000, meet international standards to support this pest-free recognition. Washing of potatoes and application of a sprout inhibition product were also recognized as appropriate risk mitigation measures for the movement of fresh potatoes from an area where a soil-borne pest, such as potato wart or PCN, has been found.

“The PEI Potato Industry believes that Ottawa must accept the findings of the expert report it commissioned and start work immediately, in collaboration with the province and industry, to lift unnecessary restrictions on farms with no connection to potato wart and implement science-based recommendations to contain and eventually eradicate the pest. PEI potato growers should not have to spend another season dealing with unnecessary restrictions due to government over-reach” says John Visser, chair of the PEI Potato Board.

The International Panel spent a week on PEI in August 2022 attending in-person information sessions, making site visits to

seed, table and processing potato farms, and visiting the Canadian Food Inspection Agency (CFIA) testing lab and local processing facilities. Panelists observed firsthand the CFIA soil sampling operations and cleaning and disinfection practices when equipment moves from regulated fields. The meeting provided the experts with a thorough look at the management of PEI fields under the Potato Wart Long Term Management Plan as well as tuber surveillance programs.

After the visit, numerous followup virtual calls were held in the fall of 2022 for clarification of Island practices and policies. The final report provides recommendations on the use of international standards to maintain the pestfree status, and recommendations to improve the management of regulated fields and outlined areas for future research.

The Panel’s report concluded that although there is a low level of potato wart infested fields on PEI (less than 0.6% of the potato

land over the 22 years since the first detection), PEI may continue to be described as a location where the pest, Synchitrium endobiotiucm, is “Present, not widely distributed, and under official control” as per International Standards for Phytosanitary Measures 8 (Determination of Pest Status in an area).

The PEI provincial government has also already taken an important step in adopting one of the Panel’s recommendations to

ensure that the limited number of infected acres be removed from potato production.

The industry is eager to get to work with federal officials to develop the plan forward for PEI farmers. The industry calls on the Canadian government to act in an efficient, timely and transparent manner for the good of Prince Edward Island and the good of the Canadian agricultural sector.

Source: PEI Potato Board January 23, 2023 news release

U.S. greenhouse operators must adapt to more foreign competitors and maturity in consumer demand

US tomato per capita consumption declined in recent years, but the greenhouse portion grew at a 5% CAGR

The U.S. greenhouse industry makes up a thin slice of the tomato, cucumber, and bell pepper market pie. In recent years, Mexico has become a force majeure in American markets of these vegetables, not only in the open-field segment, but also in the greenhouse segment writes Almuhanad Melhim, Rabobank analyst for fruits, vegetables and tree nuts.

The growth and composition of American consumers’ per capita availability of these

vegetables also tells a story of plateaued demand and a slowing substitution from open-field to greenhouse products, with Mexican imports responsible for most of the growth.

In his December 2022 report, he says that greenhouse premiums have increasingly come under pressure and are relatively low for tomatoes, signaling price sensitivity to supply expansion. The greenhouse industry’s market value growth has slowed down accordingly after doubling over

the last decade.

Implications and key takeaways

Demand maturity and increased supply competition will likely drive more consolidation in the industry to achieve growth. New U.S. entrants have to operate at a large enough scale and a high level of technology to compete in the marketplace.

U.S. incumbents and new entrants would benefit from differentiating their businesses via

Pure Flavor acquires 25-acre bell pepper farm

Greenhouse fruit and vegetable company Pure Flavor has acquired DeTemporada Farms, a 25-acre greenhouse bell pepper farm located in Merlin, Ontario.

“We are excited to announce the addition of DeTemporada Farms to our family,” said Jamie

Moracci, president. “Increasing our owned acreage helps facilitate our growth alongside our grower partners and supports our strategy of scaling up our operations to drive efficiencies. The company’s strategic investments are focused on solidifying its future as an

industry leader.”

Built in 2021 and located near the shores of Lake Erie, just east of Point Pelee, Ontario, DeTemporada Farms is in an area known for having a unique micro-climate that positively impacts the growing

the introduction of new varieties with improved attributes, branding, and using a marketing strategy to offer non-price benefits. They are also incentivized to diversify their crop mix, exploring other crops with higher growth potential.

Further, the U.S. greenhouse industry might also benefit from adopting the Dutch and Canadian ‘hub’ model rather than

remaining spatially fragmented.

Finally, forging alliances and marketing relationships with growers overseas would also aid businesses in leveraging the competitive advantages of various production regions, increasing the marketing window and reducing the cost of production.

Source: RaboResearch, December 2022

environment. Built using state-ofthe- art greenhouse technology, the facility will grow red, yellow, and orange sweet bell peppers. Expansion is already underway for the farm’s next phase that will be completed later in 2023.

“We need to strategically invest in our growth and with the acquisition of DeTemporada Farms, we are making a commitment to both our retail partners as well as our employees that we are planning for our future,” commented Jeff Moracci, chief financial officer & partner.

Pure Flavor is on a significant growth path to support increased demand for fresh, greenhousegrown fruits & vegetables yearround. Future expansion plans

beyond the DeTemporada Farms acquisition are ongoing to develop more region-specific facilities as well as explore new product opportunities.

The addition of 25 acres of owned acreage to the company’s expanding portfolio will mean an even greater supply of fresh vegetables for its customers. This new acquisition is on top of the construction of Pure Flavor’s new Phase IV 40-acre organic greenhouse in Leamington, Ontario that is nearing completion in January 2023. Through its owned farms and family of growers, Pure Flavor now manages nearly 1,000 acres of greenhouse grown fruits and vegetables.

Deactivating virus-infected greenhouse waste is first step to a second life

KAREN DAVIDSONThe discovery of Tomato Brown Rugose Fruit Virus (ToBRFV) in Ontario greenhouses in 2019 upended the sector in more ways than one. Biosecurity was quickly tightened, but the question was what to do with infected rockwool substrate at the end of its life cycle. About 36,000 metric tons of the waste –vines, spent fruit and growing media – are sent to landfills every year.

That problem was tackled by the Ontario Greenhouse Vegetable Growers (OGVG) and Walker Industries, thanks to a grant from the Greenhouse Competitive Innovation Initiative (GCII) delivered by Agricultural Adaptation Council. A three-year study has recently concluded that a proprietary composting process can not only deactivate the ToBRFV in spent stone wool substrates, but that the materials can be composted for another life cycle as growing media.

“We’re excited that this end product can be used in a circular economy,” says Erin Agro, growing media group manager, Walker Industries. “But most importantly, we want to build

growers’ confidence that the composted materials are free from ToBRFV and can be reused.”

Walker Industries, based in Arthur, Ontario, prides itself as Canada’s largest fully-integrated resource recovery company. Its method to process and recycle the spent stone wool slabs is to separate the stone wool from the plastic encasement and grind it to a size that can be composted and reused in a soil blend. Walker has sister companies which can package this material through wholesale and retail outlets.

Part of the research was to determine the survival rate of ToBRFV in spent stone wool substrates and infected vines when incorporated with source separated organic (SSO) waste and processed in Walker’s existing composting system.

Grodan, a leading supplier of stone wool growing media solutions for the horticultural sector, has been collaborating with Walker the past few years to bring a recycling alternative to the market. “Walker’s innovative processing line is one of the most advanced agricultural recycling facilities in North America. We’re excited for the material to be re-used in the compost and potting soil space,” notes Yianni

Monahan, product lifecycle manager for Grodan.

From October 2021 to October 2022, Walker obtained infected stone wool substrate and tomato vine waste which was inserted in mesh bags and incorporated near the center of a cell at the time of loading. Seven cell repetitions were conducted in which the cell underwent standard operating procedures for either a six-week or eight-week composting life cycle. Samples were taken from the end materials to create an inoculum for a plant bioassay study.

The bioassay verified that ToBRFV was fully deactivated in both the six-and eight-week compost trials. Success was attributed to the fact that Walker’s composting system achieved temperatures in excess of 75°C, for more than 40 per cent of the compost processing time.

“I congratulate Walker Industries and the Ontario Greenhouse Vegetable Growers for collaborating to develop this innovative composting project that will benefit the agri-food sector and enhance sustainability over the long term,” said Ontario Minister of Agriculture, Food and Rural Affairs Lisa Thompson. “I am delighted that this project was

made possible through the Greenhouse Competitiveness and Innovation Initiative, a great example of a leading-edge approach that will increase agrifood innovation and adoption.”

With these research results in hand, Walker Industries continues to investigate potential beneficial end uses for composted stone wool. Of most interest to the Ontario greenhouse vegetable

BC growers to pay Japanese export market pepper levy

The British Columbia Vegetable Marketing Commission has been funding the annual inspection for tobacco blue mold that is a requirement to keep the Japanese market open for BC greenhouse bell pepper imports. British Columbia is the only region in Canada that is permitted to ship product to the Japanese market. The Commission has paid the cost of this audit since

market access was granted in 2017. To be fair to all producers, this cost should now be paid by the bell pepper industry. For the 2023 crop year a small administrative levy of $0.01 per M2 is to be charged to all greenhouse bell pepper producers to cover the cost of the audit. The Commission will monitor how much product is annually shipped to the Japanese market, with the intention to

industry, the company is exploring options for end-ofcrop-cycle waste collection and processing in the Windsor-Essex area. The ultimate success story will be to offer sustainable and safe alternatives to landfilling and incineration.

eventually adopt a levy structure that is partly tonnage based so that a portion of the cost is covered from levies collected on actual shipments.

Source: BC Vegetable Marketing Commission January 17, 2023 newsletter

FRUIT LOGISTICA

The best and brightest of fresh produce innovation

Each year, Fruit Logistica holds a contest for best innovation, with a jury picking the top 10. Then it’s up to show attendees to vote for their favourite. This year’s winner will be announced February 10, 2023 in Berlin, Germany.

Here are the nominations:

Brocomole Y si de Bouquet

Anecoop, Spain · Hall 18, B-01

A new dip alternative for lovers of guacamole. The addition of broccoli to guacamole reduces its carbon footprint by more than 50 per cent since growing broccoli requires fewer water resources. Brocomole is made from 97 per cent fresh broccoli and avocado. It is a source of fiber, vitamin C, and potassium.

www.ysibouquet.com

Avisomo Growth Station

Avisomo, Norway · Hall 3.1, A-10

The Avisomo Growth Station is a fully modular, scalable, flexible, and automatable vertical farming system. It enables growers worldwide to produce any crop without changing infrastructure, at any scale and degree of automation.

www.avisomo.com

Q Eye Smart

BIOMETiC, Italy · Hall 4.1, B-31

Q Eye Smart is the only scanner entirely based on an Artificial Intelligence platform, allowing more precise and automatic fruit quality sorting. Its innovative technology substantially upgrades the entire sorting process and assures top-quality produce.

www.biometic.com/food-inspection-systems/opticalsorter-q-eye-smart

LEDFan Greenhouse Toplight – 2022 design

Food Autonomy, Hungary · Hall 3.1, A-50

LEDFan offers savings on lighting and heating costs through a highly efficient design that utilizes heat loss with controlled fans. The light fixture has a wireless control system with grid-based BMS positioning and light failure detection. https://foodautonomy.org/en/products/greenhouse-ledfan

Dutch Premium Quality Vanilla

Koppert Cress, Netherlands · Hall 3.2, C-01

An exclusive range of premium Dutch vanilla of the Planifolia variety, a species of orchid that forms pods only

after three years. This vanilla is comparable to a semi-dry muscat grape: it is not yet a raisin, but much more. In principle, it is grown in the same way as the black variety, but because it is harvested much later, the taste is different.

www.koppertcress.com/en/travel-stories/super-vettevanille

Pfannenspargel

Märkische Höfe Beelitz, Germany · Hall 20, A-23 Green and white asparagus pieces pre-cooked in their juice ready for cooking. This gives a more intense flavour with a longer shelf-life. Whether as a main course or a side dish, the pan-fried asparagus can be expanded as desired and arranged individually in a short time.

www.spargel.farm/en/about-us

evolutionS

Packaging Automation, UK · Hall 2.1, C-01

Using Packaging Automation’s new Syncro technologies, the evolutionS optimizes every step required to seal a shell accurately, reliably, and efficiently. It is considered the most technically advanced, single-lane tray sealing machine with the highest speed currently known.

www.pal.co.uk/tray-sealing-machines/evolutions Tatayoyo

OR Apple Juice Fill Up

Oranfresh, Italy · Hall 4.1, A-15

An automatic self-service machine that supplies freshly made apple juice in bottles from fresh apples, with an added solution of water and ascorbic acid (Vitamin C) to prevent natural oxidation. www.oranfresh.com

Rijk Zwaan, Netherlands · Hall 1.2, D-13

Tatayoyo is the brand name for peppers with a distinct and strong flavour. The peppers are an intermediate size between the block and snack peppers. Their special flavour comes originally from wild peppers. Ideal as a hearty snack.

www.rijkzwaan.com/tatayoyo

IDEAL Melons

Syngenta Seeds, Netherlands · Hall 1.2, C-50

Syngenta’s IDEAL Melons concept, with its Harvest Indicator feature, is a patent-pending innovation that signals readiness at each step: when it’s ideal to harvest, ship, stock on shelves, and eat. The latest game-changer in cantaloupes is now available.

www.syngentavegetables.com/brands/IDEALMelons

Talks to follow

Dr. Patricio Munoz will use consumer panel, metabolite, and genomics information to demonstrate the importance of metabolites (volatiles) on flavour and consumer experience, and future research. A plant breeder for 17 years, he currently leads the University of Florida’s blueberry breeding program. Apart from developing and releasing improved cultivars, he focuses on research using advanced methods of breeding, and training the next generation of plant breeders.

The University of Florida’s blueberry breeding program is where the southern highbush blueberry category (low chill) was developed.

Richard Bright, the editor of Reefer Trends offers his unique perspective on recent developments in the reefer shipping market and considers the future viability of both conventional and containerised modes of refrigerated ocean transport.

BITS AND BITES

More than a Migrant Worker project seeks farms for 2023 interviews

KELLY DAYNARDAs the project enters its third year, the committee working on the award-winning More than a Migrant Worker (MTAMW) campaign is looking for new seasonal agriculture workers to profile. If you have a farm or business that employs seasonal or temporary foreign workers, we’d welcome hearing from you about your dedicated employeeswhether they have been with you for one season or 30. In 2022, photo/video shoots were held in greenhouses and on berry, apple, potato, asparagus and grape operations with interviews done for 50 workers and six growers.

The More than a Migrant Worker project enables the public to learn more about the women and men who help Ontario farmers grow our food and find answers to their questions about seasonal workers on Ontario farms. It is a project of the Ontario Fruit & Vegetable Growers’ Association, in

Newsmaker

The North American Blueberry Council (NABC) has announced the full slate of its recently elected board of directors, including new president Pat Goin of Goin’s Blueberry Lane in Indiana, and other board officers. Starting in 2023, the board has been expanded from six to 15 members.

Canadian Jason Smith, Fraser Berry Farms, Abbotsford, BC. joins the board. The fourthgeneration farmer is also chair of the crop protection committee of Fruit and Vegetable Growers of Canada.

In addition to Pat Goin, the 2023 executive board includes:

• Teddy Koukoulis, chair elect, Fabulous Farms LLC

• Ellie Norris, secretary, Norris Farms LLC

• Art Galletta, treasurer, Atlantic Blueberry Co.

• Ken Patterson, past chair, Island Grove LLC

Newly elected members of the board include:

• Tom Avinelis, AgriCare Inc.

• Chelsea Consalo, Consalo Family Farms

• David Jackson, Family Tree Farms

• Brittany Lee, Florida Blue Farms

• Jason Smith, Fraser Berry Farms

• Cesar Ortiz Mendoza, Aba Value/Berries Paradise

• Bo Slack, California Giant Berry Farms

• Ryan Lockman, North Bay Produce

• Derek Eisele, Scenic Fruit

• Todd Sanders, California Blueberry Commission

partnership with Farm & Food Care Ontario and several OFVGA members.

MTAMW allows Canadians who have never met a migrant worker to see the faces, hear video interviews and read the stories of the extraordinary people who do so much for the fruit and vegetable industry in our great province. In each case, the workers review and approve their stories before they’re used publicly.

These stories are shared through Instagram, Facebook and

Twitter, as well as the MTAMW website. The project has had a reach of more than 370K people on Facebook last year. YouTube now has 41 videos on the More than a Migrant Worker channel –with 2300+ views.

If you’d like more information about this project or have a farm and its workers to suggest, reach out to Farm & Food Care Ontario’s executive director Kelly Daynard –kelly@farmfoodcare.org or by phone at 519-837-1326, extension 224.

Farm Credit Canada shares top 10 charts to follow in 2023

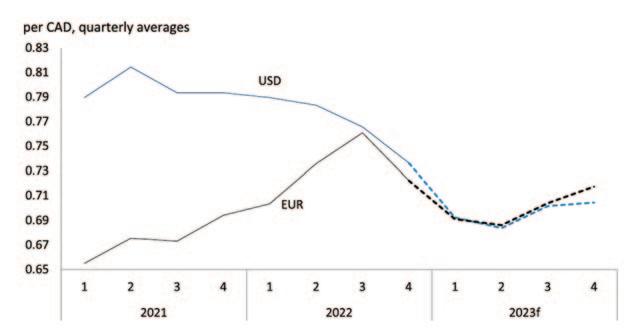

FCC Economics is highlighting 10 charts that help make sense of the economic environment for farm operations, agribusinesses and food processors. Martha Roberts, economics editor, provided analysis. Here are two of those charts. For the full report, link here: https://bit.ly/3GAmW3m

Inflation

This should surprise nobody. Last year’s inflation hit monthly highs not seen in decades, with headline inflation at 6.8% yearover-year (YoY) in November. Excluding food and energy, prices rose 5.4% over the same timeframe. Higher prices for food and

gasoline (which rose 11.4% and 13.7% year-over-year, respectively) drove much of the overall inflation as of March 2021 and throughout 2022.

Interest rates

The overnight interest rate rose from 0.25 in January 2022 to 4.25 in December 2022. Over that time, the yield has exhibited a negative slope for bonds with a maturity over one year, which means that long-term interest rates are lower than short-term interest rates. Such a pattern can serve as a signal of a looming recession as investors expect economic activity to fall over time.

FCC Economics forecasts inflation to moderate throughout 2023, although prices are still expected to remain high. Keep an eye on the Bank of Canada (BoC) as it attempts to wrest inflation under control and bring it to the midpoint of its 1 – 3% target range. The BoC is expected to keep the overnight interest rate (OIR) above 4.0% and evaluate how the economy and inflation react before considering its next move. Any further upward or sideways movement in inflation could be met by further rate increases. The next rate increase, if any, will be announced January 25, 2023.

That may not be the case in 2023 though. Because inflation

skyrocketed in 2022, the negative slope might be less a harbinger of economic fallout and more an indicator that inflation’s wild upswing is expected to moderate and, possibly, that normality will be restored.

The loonie

This is a chart that’s hard to miss on the watch list. The loonie started 2022 at 0.79USD before finishing the year just under 0.74USD. FCC Economics expects some further deterioration in early 2023. It should decline towards 0.70USD in Q2 2023 before starting to rise again by the end of 2023.

Although the CAD had appreciated relative to the Euro and several other key ag producing countries’ currencies throughout 2022, its recent fall against the Euro has eroded almost all gains. It’s a dual-edged sword, as the relative depreciation of the loonie makes imports from these countries more expensive in Canada but makes Canadian exports relatively more competitive in global markets.

Input costs

Fertilizer production has faced numerous, severe supply shocks since the pandemic that have culminated in skyrocketing prices. From weather-related damage in U.S. and Pakistani fertilizer plants and an extended Chinese phosphate export ban to the impact from the war in Ukraine on Russian natural gas exports, global fertilizer producers have been largely unable to keep up with demand.

While Dutch natural gas prices declined significantly in Q4 2022, these prices in other European centres will continue to be volatile, limiting further EU fertilizer production. EU natural gas prices will set the floor price for global ammonia and other fertilizer products in 2023.

U.S. distillate stocks (for example, diesel and heating oil) declined in September, October and November of 2022 to levels not seen since the 1950s. The low stocks have pushed diesel prices significantly higher, with the spread between gas and diesel over $0.50/litre in December. We’re watching this as diesel is the primary fuel of the economy and low distillate stocks will continue to keep inflated energy prices elevated. Going forward, the supply of diesel in the U.S. and globally is set to tighten even further with the EU embargoes on imports of Russian diesel starting in February 2023.

Farm equipment inventories

Supply chain disruptions have been a big news story each of the last two years, and in 2023, the Canadian agri-food chain may have a chance to get ahead of some of the upheaval. Our last chart to monitor this year is the trend in the value of unfilled orders of Canadian agricultural implement manufacturers. The trend is a proxy for farm equipment sales and inventory levels as it indicates the status of equipment manufacturers’ pre-orders.

Equipment sales have been mixed in 2022 following a strong performance in 2021. Continued strength in crop receipts in 2022 supported demand for new and used farm equipment. At the end of 2022, inventory levels of new farm equipment were nearly 50 per cent below their five-year average and are expected to remain tight through 2024. Farm equipment sales in 2023 will largely depend on the speed of supply chain recovery and equipment manufacturers’ deliveries on previous orders. Strong farm equipment sales in Canada and the U.S. are expected to reduce farm equipment inventories of new and used farm equipment further.

Record high product costs and supply chain issues stall program restart

DAN TUKENDORFThe Northern Fruit and Vegetable Program (NFVP) provides a fresh fruit and vegetable snack to nearly 500 schools serving more than 81,000 students in northern Ontario. The program is offered weekly from January to June as a voluntary health promotion program that is fully funded by the Ontario Ministry of Health (MOH).

The NFVP is designed to address higher incidences of childhood illnesses such as obesity and diabetes related to inadequate diet due to lack of healthy food access in northern Ontario.

For the 2022/2023 school year, the Ontario Fruit and Vegetable Growers’ Association (OFVGA) continues its role to procure and distribute the fresh fruit and vegetable snacks for the NFVP on behalf of the MOH as part of a long-term funding agreement. Now in its seventeenth season, the program is offered to elementary schools across northern Ontario in both road access and remote fly-in communities. The area serviced is covered by seven public health units including Northwestern, Thunder Bay District, Algoma, Sudbury District, Porcupine, Timiskaming and North Bay Parry Sound. This includes more than 65 First Nation communities.

The public health units work with the schools to provide inclass education resources related to diet and physical activity along with tracking student fruit and vegetable consumption rates over the course of the school year.

This past fall, 2022, the new school year began with the easing of pandemic restrictions which had disrupted the program the past two years. The program didn’t operate at full capacity due to school closures and reduced student attendance so there was sufficient program funding to look at an early November start instead of the usual January launch.

However, the plan of an early start was challenged by a spike in already inflated product costs and an increase in supply issues. A plant virus outbreak in California in conjunction with major weather events across key North American growing areas put those plans on hold. The program eventually restarted in early January 2023 and continues to be challenged with historically high product costs and unstable supply with little relief in sight.

The program attempts to provide the students with a wide assortment of fresh fruits and vegetables. The weekly menu is kept flexible in order to adjust to unexpected fluctuations in product costs and supply

disruptions. Maintaining good communications with suppliers, distributors and the schools has been key to ensure everyone is up-to-date on any changes to the weekly plans so they can adjust their program activities as needed.

Dan Tukendorf is the program manager, Ontario Fruit and Vegetable Growers’ Association. NORTHERNJoin OFVGA at its first in-person AGM in three years

And although the OFVGA provides regular email updates and reports in The Grower about our ongoing activities, the AGM is also your chance to hear firsthand from your board of directors and section chairs on the work we’ve been doing on your behalf this past year.

approvals, and the need for better energy infrastructure in rural areas.

February is annual meeting time for the Ontario Fruit and Vegetable Growers’ Association (OFVGA) and for the first time in three years, we’ll be gathering again in person for this event.

The Annual General Meeting (AGM) is an opportunity to participate in discussions around resolutions, for our voting delegates to help shape the activities and direction of the organization for the year ahead, and for everyone to have a chance to meet new faces and reconnect with familiar ones.

Here are some highlights: The Progressive Conservative election win last spring returned many familiar faces to the cabinet table at Queen’s Park. Since that election, we have been able to build on many existing relationships that have been established over the past five years, which is a valuable asset as we continue our work to bring the issues and challenges of Ontario’s fruit and vegetable growers onto the government’s radar.

This past year, the OFVGA was able to return to focusing on other issues beyond the COVID19 pandemic, one of which is the overall competitiveness of our industry. This includes inflation and the rising cost of inputs, the challenges and inconsistencies of environmental compliance

Together with our Ontario Agriculture Sustainability Coalition (OASC) partners –Beef Farmers of Ontario, Grain Farmers of Ontario, Ontario Pork, Ontario Sheep Farmers, Veal Farmers of Ontario – we have asked the provincial government to increase its investment into Self-Directed Risk Management (SDRM) and the Risk Management Program (RMP). It’s a safety net that growers depend on to deal with the kind of uncertainty that we’re currently facing, and we’re encouraged by the progress achieved so far in our work with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA).

In tandem with rising production costs has been the issue of food inflation. Food costs continue to increase at stubbornly high levels, but they’re not translating into higher prices for growers. We’ve tried hard to get that message out to Ontarians, including through an op ed that

we were able to get printed in the Toronto Star, Niagara Falls Review, and the Kitchener Waterloo Record, as well as posted on Reddit and a few other sites.

Also affecting our competitiveness is the impact of excessive red tape, such as inconsistent interpretation and application of Environmental Compliance Approvals (ECAs). We understand the need for environmental performance, but it must be balanced with the need to produce food and to ensure farmers aren’t buried under excessive bureaucracy and long approval times.

Our province is also in dire need of upgraded energy infrastructure so that growers –particularly in the greenhouse sector – can adopt more sustainable technologies, reduce their energy costs and ultimately, grow more food.

We continue to work closely with Fruit and Vegetable Growers of Canada on topics of national importance, such as continued access to crop protection tools and seasonal

agricultural workers, development of a code of conduct for the grocery retail sector, and getting legislation passed that will ensure financial protection for growers in cases of buyer bankruptcy.

Overall, we recognize that as an industry, we need to talk more about what we do, why we do it, and why protecting our domestic food production capacity is so critically important. We started down this path in 2021 with the More than a Migrant Worker initiative and we are now turning our focus to other issues with a more targeted and strategic approach to external communications.

If you haven’t already, I encourage you to consider participating in the OFVGA AGM this year. It will take place on February 21 at the Hilton Niagara Falls/Fallsview Suites, just one day ahead of the Ontario Fruit and Vegetable Convention, and registration is available at ofvga.org.

I look forward to seeing you there!

Drone partnership gives grassroots technology a new buzz

such as soybeans, corn, alfalfa and canola.

In North America, drone regulatory approval is advancing slower than drone technology development. Nonetheless, the BVT-Agri Spray partnership underlines how imaginative and mutually beneficial industry collaborations can work in producers’ favour. It also shows the ripple effect of good research.

product.

Seven years later, BVT’s CR-7 was the first agent to be approved in the U.S. for a commercial food crop protection product applied to flowering crops by live bees.

of non-pollinated crops, drones address some ongoing challenges for producers.

yields is a winning combination.”

Bees and cutting-edge technology are rarely mentioned in the same breath, let alone found under the same roof. But that could change, thanks to a new step in the evolving world of agricultural drone technology.

In the fall of 2022, Bee Vectoring Technologies (BVT) International, a company with roots at the University of Guelph, announced a partnership with Missouri-based Agri Spray Drones, which operates heavy drones in custom applications. The companies said they were coming together to trial the drone application of BVT’s proprietary Clonostachys rosea CR-7 biological fungicide on large-acre field crops

Here’s why. BVT is at the forefront of apivectoring, a crop protection system that uses bees from managed hives as a transport mechanism for biological agents that suppress pests on crops. The technology goes back to the 1980s, when Guelph environmental biologists Peter Kevan and John Sutton were looking for novel ways to deliver biological fungicides to plants.

The researchers knew pollinating and flower-visiting insects can carry and spread disease. So, they figured that maybe insects could also be employed to prevent disease by distributing natural fungicides instead. Their design for a distribution system was refined by BVT Inc. after the company acquired the rights in 2012 to develop it into a commercial

And now BVT is broadening its horizon and joining the drone movement. In a news release, BVT CEO Ashish Malik says the company has been working on delivery methods other than bees, including foliar, soil-applied, seed treatment and now drone applications.

“This exciting development is part of our overall strategy to maximize the utility of our core patented asset, CR-7, and expand its application into non-pollinated crops, providing farmers an additional sustainable tool to control pathogens and improve yields,” he says.

Bee-based distribution pushes so many of the right buttons. It provides what research pioneer Kevan calls “a double benefit to agriculture” – that is, crop pollination and crop protection acting together to increase yields and quality. And it’s hard to argue with the wholesome image of bees going about their business and delivering biologicals in such a highly targeted manner.

But for large-scale applications

As BVT points out, drones are fast and non-invasive. They can access fields in wet conditions where ground tractors can’t go. They can fly just above the canopy, minimizing overspray or drift. They help address labour shortages. All these are huge management issues.

And despite regulatory caution, drones are catching on. BVT says the global agricultural drone market, valued at more than US $1.3 billion just three years ago, is expected to reach US $10.5 billion by 2028. As it grows, companies such as Agri Spray will be looking to carve a niche. That’s something it says BVT provides in spades with CR-7.

“We are very excited to trial [BVT’s] biological fungicide CR7 via our new T40 drone because of its ability to control pathogens in multiple crops on its own or in tandem with conventional pest and disease control programs,” says Agri Spray sales manager Alex Bennett. “The capability to deliver this via drone to help farmers fight a broad spectrum of diseases and stimulate plant growth, resulting in greater crop

Guelph’s Kevan is enthused about the potential for this technology. He says he and Sutton anticipated developments of some sort would follow their groundbreaking work. Of course, neither of them predicted a connection with drones, which were still other worldly some 40 years ago when their research began.

Today though, Kevan calls BVT’s interest in drone technology “a door that is well worthwhile opening.

“As a guess, I think it might have more potential than pollination by spraying, which requires having viable pollen to spray,” he says. “There is a lot that needs to be done by way of research and development for pollen harvesting and viability.”

BVT has applied for Canadian registration for CR-7 and is waiting for review.

Owen Roberts is a past-president of the International Federation of Agricultural Journalists and a communications instructor at the University of Illinois.

FarmFood360° tours offer online opportunity to tour farms

the award-winning FarmFood360.ca website gives Canadians the chance to tour real, working farms and food processing plants, all without putting on boots or biosecurity clothing.

The potato tour starts at an Alliston-area potato farm and then visits an Ontario company turning potatoes into potato chips.

All of the FarmFood360° tours were featured at Farm & Food Care Ontario’s booth at the Royal Agricultural Winter Fair, where there were lineups of children excited to see farms through 3D goggles. The tours are all available for viewing on a monitor or smartphone as well. For each of the tours, teachers can find educator’s guides made in partnership between FFCO and Agriculture in the Classroom Canada. Even farmers can learn new things by virtually touring a farm that produces something they have not seen before.

Feb 6-7 Empire State Producers Expo, Oncenter, Syracuse NY

Feb 8-10 Fruit Logistica, Berlin, Germany

Feb 12-15 International Fruit Tree Association Annual Conference & Tour, Amway Grand Plaza, Grand Rapids, MI

Feb 13 PEI Potato Conference, Credit Union Place, Summerside, PE

Feb 14 Canadian Greenhouse Excellence Network (CGEN) Summit, Lord Elgin Hotel, Ottawa, ON

Feb 15 Canada Agriculture Day

Feb 21 Ontario Fruit and Vegetable Growers’ Association Annual General Meeting, Niagara Falls, ON

AMBER ANDERSONThree new virtual reality farm tours have been launched on FarmFood360.ca providing new opportunities for curious Canadians to learn more about how their food is made. The new tours, filmed throughout 2022 on bean and potato farms and processors, as well as a broiler breeder farm, have been added to the popular website that attracts almost a million visitors each year, joining the 22 farm and food processing tours- including an apple orchard tour- already filmed and available for viewing.

The tours were developed by Farm & Food Care Ontario (FFCO) in partnership with the Ontario Bean Growers, the Ontario Potato Board and the Ontario Broiler Chicken Hatching Egg Producers Association. The project was also funded, in part, through the AgriCompetitiveness program of the Canadian Agricultural Partnership, a federal, provincial, territorial initiative.

Using 360 cameras and virtual reality technology,

At this year’s Agriculture Adaptation Council (AAC) annual meeting, a new partnership was also announced. The AAC will provide matching funding for its membership to develop FarmFood360 virtual video experiences to promote their role in the agriculture and food continuum. The program will run for two years and approve three projects per year selected from eligible applications. This program is made possible through an allocation of AAC’s Strategic Initiative Fund. This special programming opportunity will help AAC’s membership creatively share their unique stories with new audiences, helping build trust and transparency in Ontario’s food supply. Farm & Food Care Ontario looks forward to working with commodities that apply for this exciting opportunity.

Amber Anderson is communications manager, Farm & Food Care Ontario.

Feb 21 Berry Growers of Ontario Annual General Meeting, Embassy Suites, Niagara Falls, ON

Feb 22-23 Ontario Fruit & Vegetable Convention, Niagara Falls Convention Centre, Niagara Falls, ON

Feb 23 British Columbia Cherry Association, Coast Capri Hotel and Conference Centre, Kelowna, BC

Feb 28 British Columbia Fruit Growers’ Association 134th Annual Convention, Penticton, BC

Mar 1 Tomato Day, John D. Bradley Convention Centre, Chatham, ON

Mar 2 Ontario Potato Conference & Trade Show, Delta Hotel, Guelph, ON

Mar 7 BC Wine Industry Insights Conference, Penticton, BC

Mar 7-10 North American Strawberry Growers Association Meeting and Strawberry Symposium, San Luis Obispo, CA

Mar 12-18 Ag Safety Week

Mar 14–16 Fruit & Vegetable Growers of Canada Annual General Meeting, Westin Bayshore Vancouver, BC

Mar 21-23 Minor Use Priority Setting Meeting, Gatineau, QC

Mar 21-23 GreenTech Americas, Querétaro Centro de Congresos, QRO México

Mar 21 Ontario Tender Fruit District 3 & 4 Annual General Meeting

Mar 22 Ontario Tender Fruit District 5 Annual General Meeting

Mar 23 Ontario Tender Fruit District 1 & 2 Annual General Meeting

Mar 30 Ontario Processing Vegetable Growers Annual General Meeting, Four Points by Sheraton, London, ON

April 25-27 Canadian Produce Marketing Association Convention & Trade Show, Toronto, ON

June Dispute Resolution Corporation Annual General Meeting

June 7 Ontario Produce Marketing Association Annual General Meeting & Summit, Rockway Vineyards, St. Catharines, ON

June 11 Ontario Agricultural Hall of Fame Induction Ceremony, GrandWay Event Centre, Elora, ON

Like a kaleidoscope, the retail landscape keeps changing

Loblaw Sobeys

Large stores Real Canadian Superstore Walmart Super Centre Costco warehouse

Loblaw Zehrs

Conventional stores

Provigo Atlantic Superstore Dominion Independent Fortinos Extra Foods

Discount No Frills Maxi

Tina Lee, CEO of T&T Supermarkets, is celebrating the Chinese New Year with anticipation for the Year of the Rabbit. On December 15, 2022, she opened the chain’s first store in Québec and the largest of its Asian-centric stores in Canada. It was strategically timed for the run-up to festivities which last from January 22 to February 5. 2023.

While T&T Supermarkets was opening its 31st store in Montréal’s suburb of Saint Laurent with 70,000 square feet of space, we also noted that Farm Boy unlocked the doors to its 45th store in Aurora, Ontario – a store measuring 28,200 square feet. These chains are both great retailers which have experienced sales growth, while developing a loyal clientele and a unique position in the market. All in the face of Walmart, Costco, discount banners and the pandemic.

Sometimes we forget, these formats are not independent like they started out. T&T Supermarkets is a subsidiary of Loblaw Companies – since July 2009 -- and Farm Boy is one of the formats owned by Sobeys –since September 2018. Although they are part of the large corporate entities, T&T and Farm Boy continue to operate more autonomously.

That is part of their success. If T&T started to look more like a Loblaw store, consumers would not see it as the destination that it is. Farm Boy occupies a unique position in the market with its private label program and fresh prepared foods. If consumers started to see Compliments and Sobeys chickens, they would not make the extra effort to visit Farm Boy.

Why retailers buy specialty stores

We have to be realistic. The large retailers make these acquisitions for a number of reasons:

• They want to generate a return and they see the profits in these specialty stores as slightly better than the conventional and discount banners.

• The specialty retailers such as Longo’s (acquired by Sobeys) or

Sobeys Safeway Thrifty Foods Foodland IGA (Quebec)

Metro Metro Plus

Fresh Co Price Chopper Food Basics Super C

Specialty T&T Farm Boy Longo’s Pete’s fine foods

Drug

Colemans Co op Save On Foods IGA (West)

Adonis Marche Richelieu Les 5 saisons

Too many to include

Rexall London Drugs Guardian Pharmasave

Other Real Canadian Wholesale Club Bonichoix Traditions Needs Marche AMI

“

In my many visits to Québec, I have been excited to discover a rich culinary culture that combines creativity and diversity and I look forward to T&T contributing to Québecers’ growing appetite for new culinary experiences and discoveries.

~ TINA LEE

T&T had a great culture of delivering a unique shopping experience. The large retailers need to learn how to do that and it is faster to buy the expertise and insights.

• Often perishable departments have unique products. Similar to the shopping experience, it can be better to learn through acquisitions.

• Specialty retailers can have great private label programs with items that will sell in other formats. Rooster brand products originated in T&T but we can now find them in our local Atlantic Superstore which is a Loblaw format.

• More volume is almost always a good thing. There are some items sold in almost every store, so if Sobeys or Loblaw can add cases to the total number it gives them more leverage with the Cokes and Pepsis of the world.

Maintaining an identity is a challenge

Every time I see a major retailer acquire a smaller chain, I feel uncomfortable. We need choice for consumers and suppliers in our industry. Competition makes everyone better and often smaller specialty stores bring a unique shopping experience to the market. They have to. They are closer to consumers and many

of them service new and growing market segments the larger retailers do not focus on. When they are acquired, we risk losing this sparkle in the market.

It is challenging for large retailers to give autonomy to the specialty stores. Big retailers focus on efficiency and stripping out costs. There is always the temptation to supply produce from the same warehouse or use the same plan o gram for snack foods. It would be more efficient. It would also be a mistake.

I remember when I was at Loblaw, there was a constant tug of war with the Fortinos stores. Similar to Longo’s, they occupied a unique position in the market. They almost got too close to Loblaw and lost their identity. Yes, they might pay .15 more per pound for grapes, but they were the grapes their shoppers wanted. When the offering started to get too close to Loblaw and Zehrs, it was a concern.

Our Canadian retail landscape

We know our food industry is dominated by five large corporations. Two of the big five are based in the U.S. although they do operate in Canada as a division. We also have some regional retailers. The following table illustrates all of the formats in our retail landscape.

Considerations for suppliers in our consolidated market

We can’t change the structure of the large retailers. The best answer for suppliers is to understand the market and work with the opportunities. If you supply one format such as Zehrs, do not assume they will offer you the opportunity at all of the other Loblaw banners. Their merchandising group will have the responsibility for some stores, but not all. In the case of Loblaw, they divide their business by market stores and discount stores with two separate groups. Zehrs belong to the market division, which includes Loblaw, Atlantic Superstore, Dominion and Independent. The market and discount divisions do know each other and can refer you from one to the other. If you want to get your products into T&T or Shoppers Drug Mart, they might not even know the person to call.

But that does not mean you cannot find the person! Ask the questions if you want to grow your business with them. Perhaps you produce some root vegetables plus the capability to produce some Asian greens. If they are happy with your products and the relationship, they can open the door for you. You might have to find the contact at T&T, but they might share insights about your

business and credibility.

One benefit of retailers operating multiple formats is they do have a need for different products and in some cases different sizes of the same product. This is why your relationship is so important. Retailers want to increase volume with reputable growers so they should help you find the opportunities within their own business. They will compare what you do for the other formats so make sure to keep a level playing field.

Watch the specialty stores in your area. You never know when one might get acquired by one of the larger retailers. This could open a door for you there. If you do service a store that gets acquired, do not get lost in the transition. Make sure they know who you are and what you are capable of.

It’s the Year of the Rabbit. Be nimble. Be quick.

Peter Chapman is a retail consultant, professional speaker and the author of A la Cart-a suppliers’ guide to retailer’s priorities. Peter is based in Halifax, N.S. where he is the principal at SKUFood. Peter works with producers and processors to help them get their products on the shelf and into the shopping cart.

What’s happening at the 2023 show

Wed. February 22, 2 pm Room 205

This 10th anniversary event will cheer on the top three submissions from the closed judging conducted at an earlier date. The judging panel, headed by a lead judge, will re-evaluate the submissions, and discuss the process and entries with the audience. Everyone gets to try their hand at a hop rub, featuring all the hop submissions. This year’s style is American IPA.

Thurs. February 23, 8 am – 9:15 am

The Lounge, 2nd Floor

My Life as a FarmHer

This year's featured speaker is Jen Smith, president and COO of Cherrylane Farms, a 400-acre operation located in Vineland, Ontario. The farm produces pears, peaches and tart cherries and includes a processing plant for juice and frozen fruit. Founded in 1907, Cherrylane has been in the Smith family for 10 generations. She has transformed the operation over the years, finding new and innovative ways to keep the farm up-to-date and relevant in today’s fruit farming and processing markets. Cherrylane has made its mark as Canada’s only producer of 100 per cent concentrated tart cherry juice. Smith credits much of her success to loyal staff mostly comprised of women. Together with her team, she has developed a highly successful, multi-dimensional business.

Thurs.

February 23, 12 pm – 1:15 pm

The Lounge, 2nd Floor The Cynic and the Dreamer

Geared to farmers 40 and under, this event is featuring Ontario’s Outstanding Young Farmers 2022. They are David and Jenn VanDeVelde, owners of Wholesome Pickins Market and Bakery in Delhi, ON. They are currently growing strawberries, raspberries, asparagus, rhubarb, pumpkins, squash. Locals from miles around migrate to their on-farm market, scratch bakery and savoury kitchen from April to Christmas. The farm offers pick-your- own, farm tours and event hosting, a real hub for the community.

What’s happening at the 2023 show

FARMERS’ MARKETS ONTARIO

Feb 22-23, Ballroom A

This association, an umbrella for about 180 markets across the province, holds its annual general meeting on Feb. 22. Speakers include Dr. Robert David, McGill University addressing the multiple logics of farmers’ markets and Dr. Laura Golding talking about the partnership between 4-Ontario and farmers’ markets. Executive director Catherine Clark will round out the session with an overview of 2022 and a new program announcement.

FARM FRESH ONTARIO

Feb 22-23, Ballroom D

This association will feature Jo-Ann McArthur, Nourish, addressing food trends and how to leverage them into on-farm markets. Dr. David Posen will talk about stress mastery and how you have more control than you think. The meeting will welcome Nicole Marenick to talk about socia media strategy. Is Facebook dead? Is TikTok just for kids? She’ll share her insight.

CIDER COMPETITION

Feb. 22 Room 203

A full slate of speakers is planned. Steven Trussler, CCOVI, will be addressing flavour and ingredient innovations in the cider industry. A panel will be sharing views on the opportunities and challenges ahead for the Ontario Craft Cider industry. Speakers are: Jennifer Dean, Matt Dixon and Matt Somerville. And finally, winners will be announced for the cider competition

RESEARCH POSTER COMPETITION

Posters that present results from research trials, including pest management, crop production, new cultivars, and opportunities for marketing Ontario horticulture are welcomed. Students compete for prizes and bragging rights. Only 20 applicants are accepted in this separate competition.

FOCUS: ONTARIO FRUIT & VEGETABLE CONVENTION

One of John Deere’s 2023 startup collaborators to be at OFVC

KAREN DAVIDSON

KAREN DAVIDSON

Canadian start-up, IntelliCulture, is five years old with nine people on board.

Headquartered in London, Ontario, the company got its start in the horticultural arena.

“Our software plugs into the machines on your farm, basically anything on wheels,” explains Cole Powers, co-founder. “That means tractors, pick-ups, implements.”

The idea is to track the operating hours of machinery and to alert managers of the most opportune time for servicing. There’s a big cost to owning equipment, but there’s also a cost

for maintenance. For example, a grower may have a sprayer or several sprayers in action in an orchard. The optimal management of that machine is to service it before there’s a costly or untimely breakdown in the field.

The IntelliCulture software is already in use on farms in Ontario, California, Oregon and Washington, with thousands of machines now under the program. Constellation Brands is one example that uses the tracking software to estimate times needed per block of grapes. The data forms a baseline for tracking operator time and calculating budgets for the following year.

Powers grew up around the

horticultural industry but has returned to his roots after working in the automotive industry. He’s particularly proud of the new Startup Collaborator program with John Deere.

“The companies we target for the John Deere Startup Collaborator are those using an innovative/disruptive business model or technology and still in the early phases of their growth, fundraising, and development,” explains Michele Kaiser, business development manager, John Deere Intelligent Solutions Group. The other Canadian company on this year’s roster is Precision AI based in Regina, Saskatchewan.

Emerging companies in the arena of precision technology

Deere & Company has released the names of eight companies chosen for its 2023 Startup Collaborator program. The Startup Collaborator was launched in 2019 to help John Deere enhance precision technology in its agriculture and construction equipment.

“This year’s group shows the

importance of connecting with the startup community across a broad range of applications and technologies,” said Julian Sanchez, director of emerging technology at John Deere. These connections help John Deere better understand opportunities to advance precision technology in agriculture and construction.”

The eight companies participating in the 2023 Startup Collaborator include:

Albedo, a startup company developing low-flying satellites that will collect visible and thermal imagery at ultra-high resolution.

ANELLO Photonics, a company that is disrupting the

navigation industry with its Silicon Photonics Optical Gyroscope, a low-noise and low-drift optical gyroscope smart sensor for autonomous applications.

GrAI Matter Labs is in the business of Life-Ready AI –artificial intelligence that feels alive, delivering brain-inspired chips that behave like humans do and makes devices assisting humans act, and react, in real time.

Impossible Sensing, an aerospace company developing and applying space technology to the agriculture industry to help the world become carbon neutral.

IntelliCulture, a company providing farm equipment management software that helps drive sustainable farming practices through actionable insights, efficiency improvements and risk mitigation.

Precision AI, a startup that’s creating the world's first artificial intelligence-powered agricultural drones for plant-level herbicide applications at broad-acre scale.

RodRadar, a company transforming excavation. Its Live Dig Radar technology provides

real-time, on-site, automatic alerts to prevent damage to underground utility infrastructure during excavation.

Vega is the window that certifies agribusiness sustainability to the world. Supporting sustainable production, Vega impacts the entire agri-food chain through traceability, risk analysis and monitoring of Environmental, Social and Governance (ESG) practices.

“The Startup Collaborator is an exciting way for big ideas to grow into something larger,” said Michele Kaiser, business development manager for the John Deere Intelligent Solutions Group. “As John Deere continues searching for new and interesting ideas, we can add value to our customers –even if we’re not sure exactly how that might look. We are trying to help farmers solve big challenges in efficient ways. To do this, we need access to a lot of great ideas, so it’s exciting to welcome these companies into the 2023 Startup Collaborator cohort and to see what we can learn from each other by working together.”

GROWER FOCUS: ONTARIO FRUIT & VEGETABLE CONVENTION

Look who’s here

Smart scanning system to monitor fruit on the tree and in the bin

All over the world, the drive towards automation and robotics in agriculture is exploding, especially with the challenge of accessing labour. Ontario's fruit tree industry is continuously looking at ways in which to improve efficiencies and fruit quality using the latest technologies. Over the past two years, Ontario Tender Fruit and Ontario Apple Growers partnered with Ontario‐based Croptracker, Inc. to develop and pilot the Croptracker Harvest Quality Vision (HQV) and Crop Load Vision (CLV) as well as Offline Mode. The project is funded in part by the Canadian Agricultural Partnership, a five-year provincial‐territorial initiative.

The innovative HQV & CLV modules use computer vision technology, algorithms and trained artificial intelligence (AI) to enable scanning of both harvested and unharvested tree fruit for quantity, colour, size and quality. One of the goals of this project was to provide scanning capabilities using common smartphone technology, something Ontario growers already have at their fingertips, versus having to buy expensive new equipment or third-party hardware. A list of compatible devices for taking CLV & HQV scans has been developed.

Crop Load Vision (CLV) module:

Successes

• Developed an in‐orchard mobile